|

High-order

Rational Harmonic Mode-locking and

Pulse-amplitude Equalization of SOAFL

under Optical Injection

Professor Gong-Ru Lin

Graduate Institute of Photonics and

Optoelectronics, National Taiwan

University

First

of all, we demonstrate the 20th-order

rational harmonic mode-locking (RHML)

semiconductor optical amplifier fiber

laser (SOAFL) pulses by using 1 GHz

backward dark-optical comb injection,

and discuss the

competition between

mode-locking mechanisms in the SOAFL at

high-gain and strong optical injection

condition at higher RHML orders.

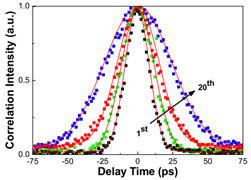

As the rational harmonic order increases

up to 20, the auto-correlation traces

and optical spectra of the RHML-SOAFL at

different RHML orders are characterized.

The Fig. 1. shows that the normalized

auto-correlation traces of the SOAFL at

1st, 5th, 10th,

and 20th RHML orders

gradually changes the pulsewidth from

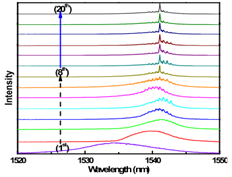

13.5 to 35 ps. The Fig. 2.

exhibits that the SOAFL spectrum with

red-shifted wavelength and reduced

linewidth from 12 to 3 nm at RHML order

increases to >8 reveal a less pronounced

high-order RHML mechanism when competing

with the continuous-wave lasing

mechanism. Furthermore, in order to

solve the problem of uneven RHML

pulse-amplitude, we use the reshaped

10-GHz gain-switching FPLD double-peak

pulse to reconstruct the gain profile of

SOA in time domain, the 4th-order

RHML-SOAFL is demonstrated for achieving

40-GHz RHML pulse-train with optimized

performance of pulse-amplitude

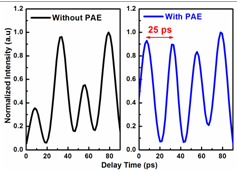

equalization (PAE). The Fig. 3. shows

the auto-correlation traces of 4th-order

RHML pulse-train without and with PAE.

Such the indirect gain compensation

further balances the amplitude

fluctuation from 45% to 3.5% when

obtaining 40-GHz RHML pulse-train.

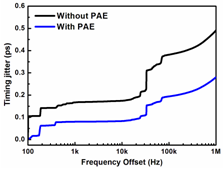

After initiating the PAE, the

uncorrelated phase noise contributed by the residual ASE noise of

the RHML-SOAFL is significantly

decreased, which leads to a timing

jitter reducing from 0.5 to 0.28 ps as

shown in Fig. 4. and provides an

amplitude-equalization pulse-train

repeated at 40 GHz to meet the demand of

being a perfect RZ pulsed carrier for

its future application in OTDM network.

Reference: G.

-R. Lin et al., Optics Express, Vol. 18,

No. 9, pp. 9570-9579, Feb. 2010.

|

|

|

|

Fig. 1. The

auto-correlation traces of SOAFL at

1st, 5th, 10th,

and 20th RHML orders. |

Fig. 2.

Evolution on RHML-SOAFL spectra at

different RHML orders. |

|

|

|

|

Fig. 3. Auto-correlatted

traces of 40-GHz RHML pulse-train

without and with pulse-amplitude

equalization. |

Fig. 4. The

timing jitter of 40 GHz RHML

pulse-train without and with

pulse-amplitude equalization. |

Emitter

Apodization Dependent Angular Luminance

Enhancement of Microlens-Array Film

Attached Organic Light-Emitting Devices

Professor Hoang-Yan Lin

Graduate Institute of Photonics and

Optoelectronics, National Taiwan

University

Taking

organic emitter apodization calculated

from electromagnetic theory as input,

the angular luminance enhancement of a

microlens-array-film (MAF) attached OLED

(organic light-emitting device) can be

further evaluated by ray-tracing

approach. First, we assumed artificial

emitters and revealed that not every

OLED with MAF has luminance enhancement.

Then, the OLEDs of different Alq3

thickness were fabricated and their

angular luminance measurement validated

simulation results. Mode analyses for

different layers were performed to

estimate the enhancement potential of

the MAF attached devices. In conclusion,

the organic emitters with higher

off-axis-angle luminous intensity cause

lower out-coupling efficiency but gain

higher enhancement after the MAF

attached.

|

Fig. 1. (a)

The simulated source apodization

varying Alq3 thickness

from electromagnetic theory; (b) the

simulated luminance from geometrical

optics; (c) the validation of

experimental results. |

|

Fig. 2. (a)

Mode ratios calculated by transfer

matrix method with embedded sources.

The blank area of each bar

represented the optical power ratio

of the surface plasmonic mode; (b)

the experimental mode ratios. |

A Novel

Boundary-Confined Method for High

Numerical Aperture Microlens Arrays

Fabrication

Professor Guo-Dung John Su

Graduate Institute of Photonics and

Optoelectronics, National Taiwan

University

We present a technique to

improve microlens arrays (MLAs)

uniformity after the thermal reflow

process. Microlens arrays (MLAs) usually

form a layered structure in

application-specific optical systems,

such as backlight modules for liquid

crystal displays (LCD), extraction

improvement film for layered light

emitting devices, wavefront sensors,

image recorders, and a focusing

component in the optical communication

devices. It is hard to make small lenses

and large arrays by traditional

machining. Although several methods are

proposed to replace the traditional

machining, thermal reflow process is

widely used to fabricate MLAs.

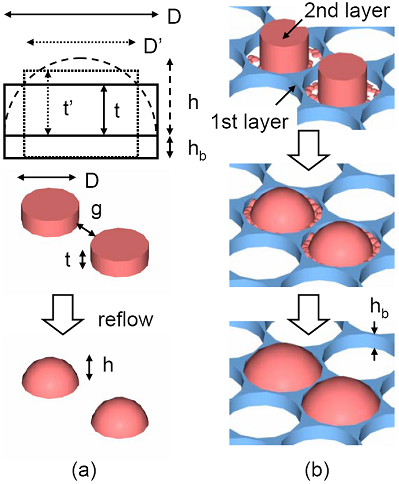

To

overcome this difficulty, a novel method

is proposed and demonstrated in this

paper. It is called the

boundary-confined method. A boundary

between each PR cylinder is defined

first by a thin negative tone PR. A

thermal reflowing of a 2nd

thick PR is halted at the boundary, as

shown in Fig. 1. The uniformity can be

improved without the cling phenomenon.

Besides, the boundary is narrow and only

a small amount of fill-factor is

sacrificed. The height of the microlens

is adjustable by the different diameter

of PR cylinders inside the same boundary

wall. We achieved high uniformity and

high-NA (numerical aperture)

simultaneously without sacrificing

fill-factor too much. In order to

improve fill-factor, residual PR (photoresist)

between the photoresist cylinders are

used to make photoresist flow outward in

standard thermal reflow processes. PR

cylinders, however, merge together

easily due to an inexact reflow time and

temperature distribution. This results

in low uniformity and small lens height

or low-NA. We proposed a

boundary-confined method to pattern thin

PR holes to prevent PR microlenses from

merging together even after a long

reflow time. Thick PR cylinders are

patterned inside thin PR holes served as

boundaries. PR microlenses are formed

after reflowing the thick photoresist

cylinders. Both the uniformity and the

height of microlens can be well

controlled. Besides, the fill-factor is

high due to the high resolution at thin

photoresist layer in photolithography.

Our results show that the microlens is

approximately a hemispherical profile.

The gap between microlenses with 48

mm

diameter in hexagonal arrangement is 2

mm

and the height of microlens is 22

mm,

as shown in Fig. 2. This work is also

patterned under US 7,713,453 B2.

|

|

|

Figure 1.

Schematic drawing of PR reflow by

boundary-confined method. |

|

Figure 2. The

fabrication process sequence, and

(a) PR microlens and SU-8 boundary,

(b) PDMS mold captured by a

microscope, (c) UV gel MLAs after

releasing from PDMS mold. |

The

Correlation of Turn on Voltage and Band

Alignment in Organic Light Emitting

Diodes

Professor Chih-I Wu

Graduate

Institute of Photonics and

Optoelectronics, National Taiwan

University

Turn on

voltage in the current density-voltage

characteristics is one of the important

factors to evaluate the performance of

organic light emitting diodes (OLEDs).

We report investigation of the origins

of turn-on voltage, defined at where log

J (current density) has a sharp rise and

starts to increase dramatically. In

OLEDs with NPB as the hole transport

layer (HTL) and Alq3

as the electron transport layer (ETL),

we find that the turn on voltage is

always at 2V, regardless the cathode

structures being used, such as Ca, Al,

LiF/Al and Cs2CO3/Al.

The turn on voltage is also independent

on the thickness of organic layers

(thickness varies from 30nm to 120 nm).

Beside NPB and Alq3,

we also study the J-V characteristics on

various OLEDs with T3/Alq3,

NPB/T3,

and NPB/Bphen as HTL/ETL, respectively.

In all the devices mentioned above, the

turn on voltage just equals to the

difference between the LUMO of ETL and

the HOMO of HTL, taking into

consideration of vacuum level shift at

organic interfaces measured from the

ultraviolet photoemission spectroscopy

(UPS). Combined with J-V characteristics

of OLEDs and UPS measurement, we

conclude that the turn on voltage of

organic light emitting devices is

determined by the difference between

LUMO of ETL and HOMO of HTL and is

independent of the cathode and thickness

of organic layers. We also found that

the charge transfers at the interface of

ETL/HTL play an important role to the

turn on voltage of OLEDs.

Emitting

Layer Thickness Dependence of Color

Stability in Phosphorescent Organic

Light-Emitting Devices

Professor Jiun-Haw Lee

Graduate Institute of Photonics and

Optoelectronics, National Taiwan

University

We

investigated the strong influence of the

thickness of iridium(III)bis[(4,6-difluorophenyl)

-pyridinato-N,C2’]picolinate

(FIrpic) doped N,N’-dicarbazolyl-3,

5-benzene (mCP) blue emitting layer (B-EML)

on color stability. The large voltage

drop across the B-EML resulted in a

higher sensitivity of the carrier

transport and injection properties to

the applied external voltage. According

to carrier mobility measurements by the

time-of-flight method, the electron

mobility of the mCP exhibited a strong

dependence on the electric field.

Therefore, at a higher driving voltage,

the more rapidly increasing electron

mobility of the mCP and the decreasing

energy barrier height on the electron

transport path would extend the

recombination zone from the B-EML to the

tris(phenylpyridine)iridium (Ir(ppy)3)

doped mCP green emitting layer (G-EML)

in devices with thinner B-EMLs. Coupled

with the fluctuations of the

recombination zone, stronger

triplet-triplet exciton annihilation

occurring in the thinner B-EMLs led to

an even more evident deterioration of

the color stability. After circumventing

these two negative factors, a green-blue

organic light-emitting device (OLED)

with ultra-high color stability was

demonstrated, with the CIE coordinates

slightly shifted from (0.256, 0.465) to

(0.259, 0.467) with increased luminance

from 48.7 to 12700 cd/m2.

Further adding a red phosphorescent

dopant into this green-blue EML

backbone, we successfully fabricated a

white OLED with high color stability,

which exhibited a nearly invariant CIE

coordinate throughout the practical

luminance range from 1050 ((0.310,

0.441)) to 9120 cd/m2

((0.318, 0.446)) and maximum

efficiencies of 26.4 cd/A and 19.8 lm/W

[published in Org. Electron. 11,

1500, 2010].

Effects

of Gate Bias and Thermal Stress on ZnO

Thin Film Transistors

Professor

Jian-Jang Huang

Graduate Institute of Photonics and

Optoelectronics, National Taiwan

University

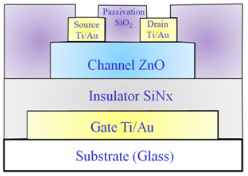

The

effects of gate bias and thermal stress

on the threshold voltage shift were

examined for ZnO TFTs fabricated on the

glass substrate. We compared three

samples with various post ZnO growth

annealing durations. The results show

that the threshold voltage shift (ΔVth)

is only 2.2V after a 1.3×104s

stress at the gate bias 20V for device

C. And the threshold voltage shift can

be correlated to the stress time

following the charge trapping mechanism.

The characteristic trapping time

τ

of device C was calculated to be 1.26×106

s. Further comparisons of the trap

states and off currents reveal that

device C has a better ZnO crystalinity

and a better ZnO/SiNx

interface quality. Finally, the

characteristic trapping time was

extracted at different temperatures for

device C. We obtain an average effective

energy barrier Eτ

of 0.57eV. The results presented in this

work suggested that excellent

τ

and Eτ

can be obtained from ZnO TFTs on the

glass substrate following our

fabrication steps.

|

|

Fig. 1: Layer

structure of the ZnO TFT on the

glass substrate.

Fig. 2:

Transfer curves at different stress

time for device A(a), B(b) and C(c).

The bias gate voltage is 20V.

Fig. 3: Time

dependent ΔVth of device

A, B and C under a gate bias 20V.

Fig. 4: Time

evolution of transfer curve during

the recovery phase of device C. The

inset shows the ΔVth

versus relaxation time. |

|

Fig. 2(a) |

Fig. 2(b) |

Fig. 2(c) |

|