|

Room-temperature

Low-threshold Current-injection InGaAs

Quantum-dot Microdisk Lasers with Single-mode

Emission

Professor Ming-Hua Mao's

Laboratory

Graduate Institute of Photonics and

Optoelectronics, National Taiwan University

臺灣大學光電所 毛明華教授

We fabricated current-injection

InGaAs quantum-dot microdisk

lasers with benzocyclobutene

cladding successfully. The

benefits of this device

planarization process are the

better thermal conductivity and

the less fragility. With this

structure, low threshold current

of 0.45 mA is achieved at room

temperature from a device of 6.5

μm in diameter with single-mode

emission from quantum-dot ground

states. Through a temperature

dependent measurement, the low

loss level of our microdisk

cavities has been confirmed.

These microdisk lasers also show

a characteristic temperature

significantly higher than that

of the edge-emitting lasers from

the same wafer. Therefore,

single-mode current-injection QD

microdisk lasers with very low

threshold current are

demonstrated and they can serve

as very suitable light sources

in a compact integrated optical

communication system. This work

has been published in Opt.

Express, Vol. 19, No. 15, pp.

14145, (2011).

|

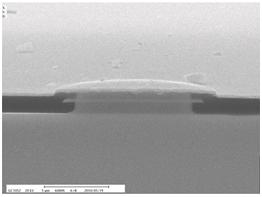

| Fig. 1. The

cross-section SEM image of a

current-injection microdisk laser

device. The microdisk diameter is 10.5

μm. |

|

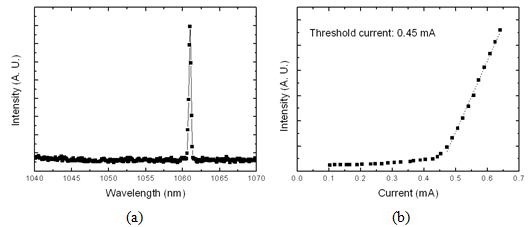

| Fig. 2. (a)

The mode spectrum of a lasing

6.5-μm-diameter microdisk. The WGM

linewidth is 0.28 nm. (b) The L-I curve

of the 6.5-μm-diameter microdisk, the

threshold current is 0.45 mA. |

Using Hydrophilic Effect to Fabricate Self-Assembled Microlens Array by UV/ozone Modification

Professor Guo-Dung Su

Graduate Institute of Photonics and

Optoelectronics, National Taiwan University

臺灣大學光電所 蘇國棟教授

Micro-lens array (MLA) is an important component and is used widely in many applications, such as increasing the light extraction efficiency, beam shaping for illumination or light gathering, wavefront sensor, and information displays. There have been many techniques to fabricate micro-lens array, including thermal reflow, laser ablation, direct laser writing, direct e-beam writing, deep lithography with protons, ink-jet printing, and gray-scale mask methods. However, there are still some drawbacks of these techniques. Thermal reflow method requires high temperature and the need for an etch-transfer process. The limited numerical aperture is also concerned. In the laser ablation, the problems are high facility cost and high energy consumption. For the ink-jet printing, the lens size and alignment accuracy are limited. It is difficult to fit the shape precisely and to distinguish the gray levels in a sharp edge by gray-scale mask method. Therefore, a fast, cost effective, stable, and focal length controllable method is desirable to fabricate MLAs.

There is another approach to fabricate MLAs using hydrophobic effect. This approach offers an attractive alternative because it allows accurate and direct fabrication of polymer microlenses without heating or post etching of the substrate. The approach is based on patterning hydrophobic molecules on a substrate and self-assembly of a liquid pre-polymer. It was affected by different surface energy on the hydrophilic domains. The techniques to create patterns include micro-contact printing (µCP) of self-assembled mono layers (SAMs) and adhesive lithography. It provided a simpler method to fabricate MLAs using the hydrophobic effect. However, it still needs either an etch-transfer process of µCP stamp or lithography for an adhesive substrate. That increases the cost and process complexity.

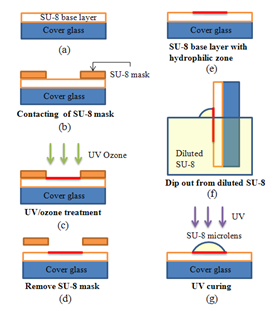

SU-8 photoresist (MicroChem, MA) has high optical transmittance from visible to near-infrared wavelength and high refractive index (~1.63). Furthermore, it has better chemical resistance and mechanical strength than other common polymers such as polycarbonate or PMMA. As a result, SU-8 photoresist is ideal for microlens array fabrication. In this work done in Micro Optical Device Lab (MODEL), a transparent and self-assembled MLA fabricated by the hydrophilic effect through ultra-violet (UV)/ozone treatment is presented. A base layer of SU-8 photoresist can be surface modified to become more hydrophilic using UV/ozone cleaner (model UV-1, Samco). Contact angles on the modified surface were ranged from 27˚ to 15˚ depending on the processing time, UV power and ozone concentration. The light source of UV/ozone cleaner is 110W with primary process wavelength of 254 and 182 nm. The oxygen flow rate is 0.5 L/min. The MLA was made of diluted SU-8 photoresist, which has refractive index mismatch from a glass substrate. This method provides a fast, low cost, no etch-transfer, no lithography fabrication processes. The focal length of MLA is controllable based on UV/ozone treatment.

|

|

| Figure 1. The fabrication process of SU-8 photoresist MLA using hydrophilic effect under UV/ozone treatment. |

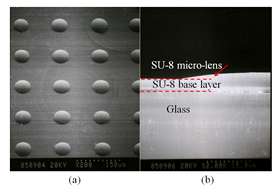

Figure 2. The SEM of (a) microlenses of 100 μm diameter under one minute UV/ozone treatment time. (b) the cross section profile of one minute treated microlens. |

The Optical Theorem in FDTD Light Scattering Simulation

Professor Snow H. Tseng

Graduate Institute of Photonics and

Optoelectronics, National Taiwan University

臺灣大學光電所 曾雪峰教授

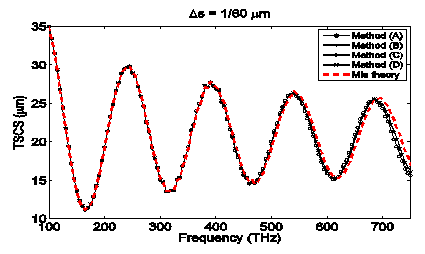

The total scattering cross-section (TSCS) is a useful parameter in analyzing light scattering properties. Here we derive a pragmatic relationship of the optical theorem to be employed in a Finite-difference time-domain (FDTD) simulation of light scattering problems. Specifically, the accuracy of the proposed TSCS calculation method is analyzed and compared with other methods. This research solidifies the theoretical basis for light scattering simulation studies.

|

| Fig. 1. Compare TSCS calculated via various methods in an FDTD simulation with grid resolution

Ds = 1/60

mm. Methods (A): Optical theorem, (B): sum of far-field RCS at all angles, (C): near-field outgoing Poynting vector flux, and (D): definition of ECS. |

|

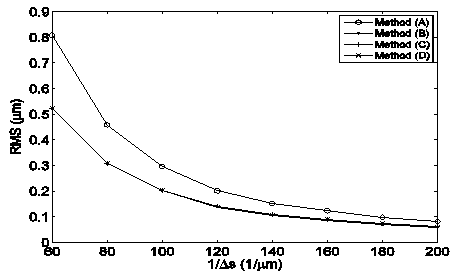

| Fig. 2. Compare RMS error of the TSCS calculation in an FDTD simulation. |

|

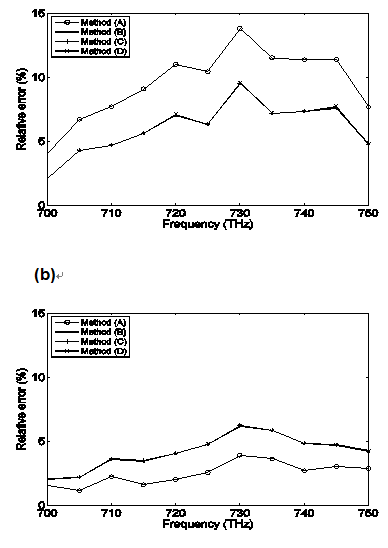

| Fig. 3. Error of TSCS calculation via various methods compared with Mie theory. The FDTD simulation is performed with an FDTD grid resolution of

Ds = 1/60

mm. (a) the error of TSCS calculated via Optical theorem is larger than others; (b) after compensating for the numerical dispersion of a frequency of 750 THz at 0 degree, the accuracy of Optical theorem calculated TSCS exceeds others. |

|

|